Hardwood from surrounding forests is brought to our facility for processing (cutting and splitting) and then dried prior to the convertion by a unique pyrolysis process into biocharcoal products.

The pyrolysis is a thermochemical process of decomposition of wood components (hemicellulose, cellulose, lignin) in the absence of air and at high temperature, which increases the carbon content until the complete conversion into biocharcoal.

Our unique pyrolysis process eliminates the need to burn inefficiently a portion of the wood to remove moisture and initiate the conversion into charcoal. This novel approach limits the production of ash and wood remains at the end of the production cycle. Furthermore, by avoiding the use of mortar and watering the biochar during the cooling stage, we ensure that our products are free of contaminants and do not generate sparks during combustion and BBQing .

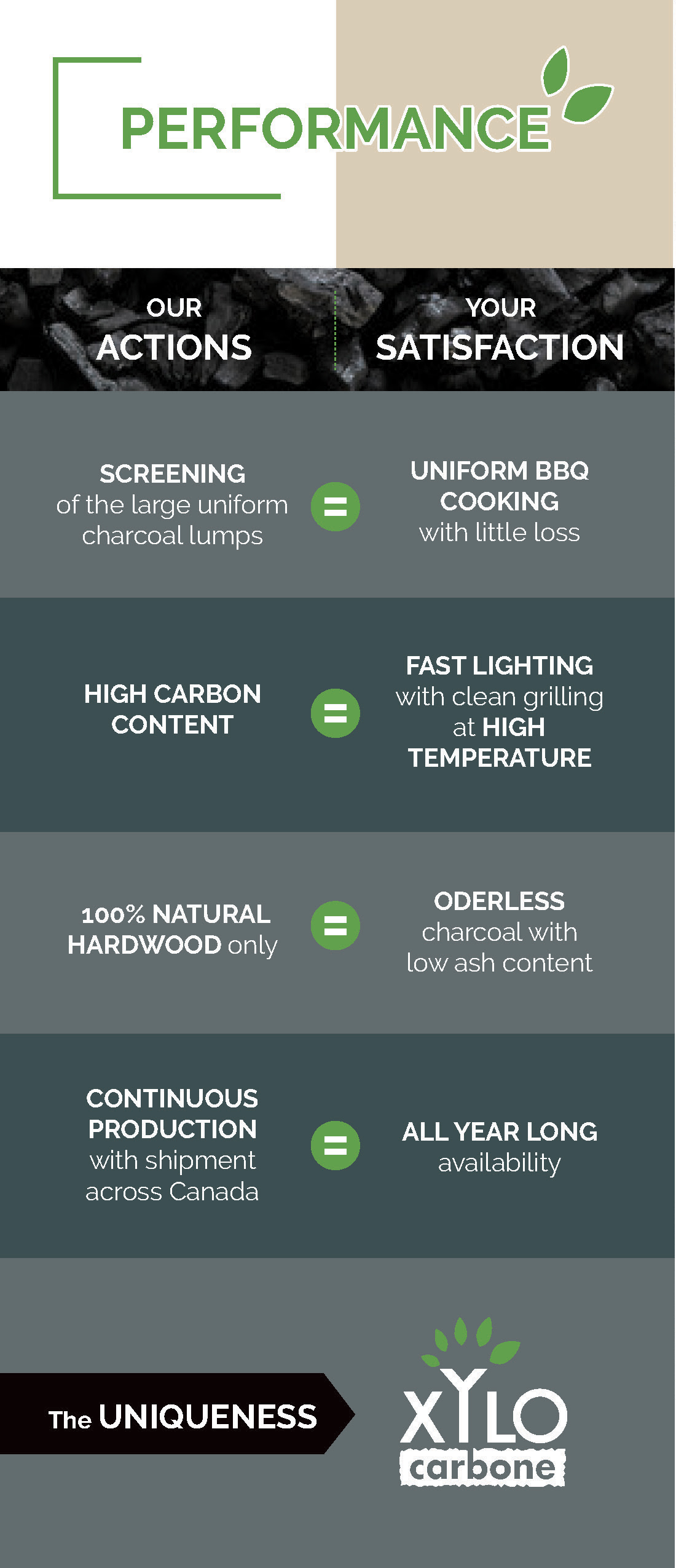

Depending on the intended applications and the specifications to be met, our products are subsequently sifted and / or micronised and / or activated to meet the specific needs of the final customers.

A novel heating process without oxygen (pyrolysis by indirect contact) allowing a maximum charcoal yield and uniform quality of the hardwood charcoal produced. Recovery of gases and other residues as a source of clean energy allowing a significant reduction in our environmental footprint. Screening of the entire charcoal production to keep the large uniform lumps for grilling and BBQing

The commissioning of our second pyrolysis unit (charcoal kiln) is scheduled for September 2020.

This investment will allow us to offer you even more charcoal in the years to come.